The Importance of a Paper Sheet Cutter in Daily Operations

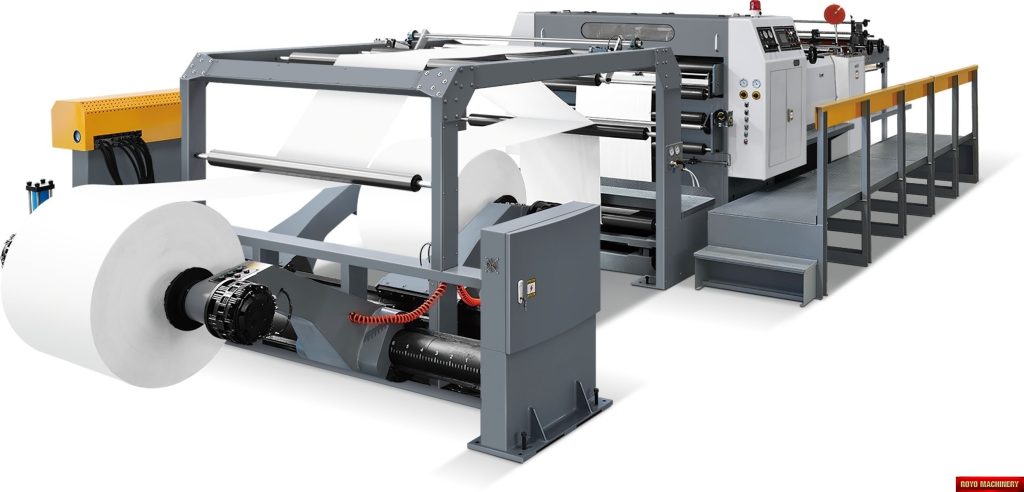

Paper Sheet Cutters are indispensable tools in numerous industries, providing precision and efficiency in cutting tasks. From offices to large-scale manufacturing, these machines streamline workflows by delivering uniform and clean cuts. Whether it’s slicing through large stacks of paper or creating precise shapes for packaging, a quality paper sheet cutter enhances productivity while minimizing errors. The ability to customize paper sizes and shapes makes it a valuable asset for businesses of all sizes.

Types of Paper Sheet Cutters and Their Features

There is a wide variety of paper sheet cutters, each designed to cater to specific needs. Manual paper cutters are ideal for small tasks, requiring a straightforward lever mechanism to trim sheets. Electric and hydraulic models, on the other hand, are tailored for industrial applications, capable of handling high volumes with ease. Advanced features like programmable settings, safety guards, and laser guides ensure accuracy and user safety. Selecting the right type of cutter depends on factors such as workload, required precision, and budget.

Benefits of Investing in a High-Quality Paper Cutter

Opting for a premium paper cutter offers significant advantages. These machines reduce the time and effort required for manual cutting, enabling workers to focus on more critical tasks. High-quality cutters also provide consistent results, crucial for professional presentations and mass production. Additionally, they are built to last, ensuring long-term reliability. By enhancing efficiency and reducing waste, these devices contribute to cost savings in both the short and long term.

Tips for Maintaining a Paper Sheet Cutter

Proper maintenance is key to extending the lifespan of a paper sheet cutter. Regularly cleaning the cutting blade and lubricating moving parts prevent wear and tear. Ensuring proper blade alignment is crucial for maintaining cutting accuracy. Users should also follow the manufacturer’s guidelines for usage and servicing to avoid potential malfunctions. Routine inspections can identify minor issues before they escalate, ensuring the cutter remains in optimal working condition for years.