Polypropylene Random Copolymer (PPR) pipes have revolutionized the plumbing and piping industry due to their durability, versatility, and cost-effectiveness. Originally developed to address the limitations of traditional metal and plastic pipes, PPR pipes offer enhanced resistance to chemical corrosion, high temperatures, and mechanical stress. This makes them ideal for a wide range of applications, from residential plumbing systems to industrial fluid transport. As the demand for PPR pipes continues to rise, manufacturers have been innovating and refining their production processes to meet the evolving needs of their customers.

Key Players in the PPR Pipe Manufacturing Industry

The global market for PPR pipes is dominated by several key manufacturers who have established themselves through quality, innovation, and customer service. Companies like Wavin, Bänninger, and Aquatherm have become synonymous with reliability and excellence in PPR pipe production. These manufacturers invest heavily in research and development to introduce new products and improve existing ones, ensuring they remain at the forefront of the industry. Their commitment to sustainable practices and adherence to stringent quality standards further solidify their reputation as industry leaders.

Innovations and Technological Advancements

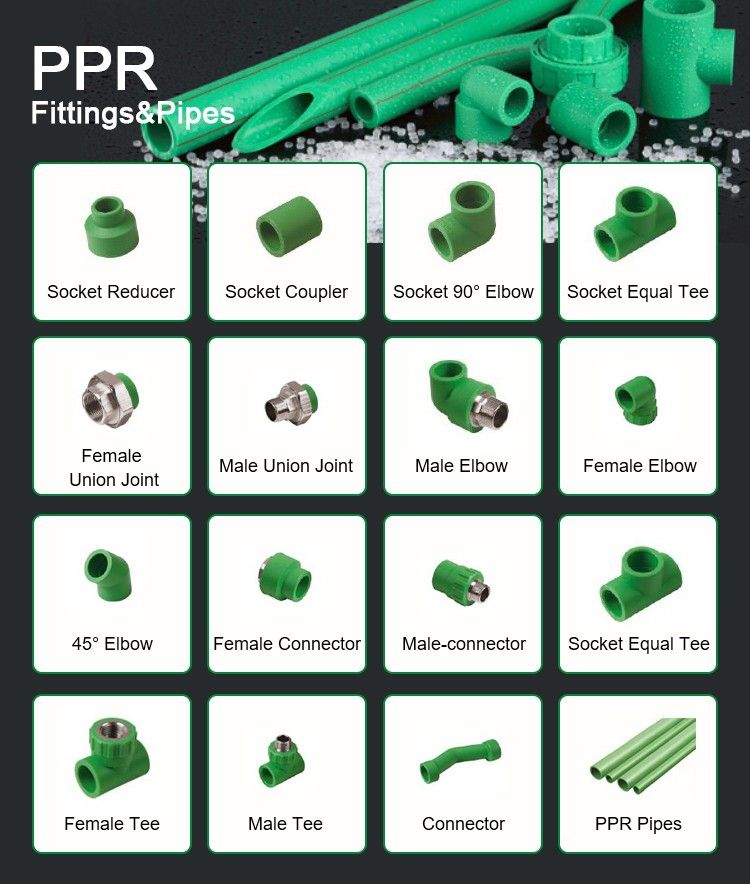

Technological advancements play a crucial role in the evolution of PPR pipe manufacturing. Modern manufacturers utilize state-of-the-art extrusion and molding technologies to produce pipes that meet the highest standards of performance and safety. Innovations such as multilayer PPR pipes, which combine different materials to enhance specific properties, and the development of PPR fittings that ensure leak-proof connections, have significantly improved the functionality and longevity of PPR piping systems. Additionally, the integration of smart manufacturing techniques, including automation and real-time monitoring, allows manufacturers to optimize production efficiency and maintain consistent quality.

Challenges and Future Prospects

Despite the numerous advantages of PPR pipes, manufacturers face several challenges, including fluctuating raw material prices, stringent environmental regulations, and intense market competition. To overcome these challenges, companies are focusing on developing eco-friendly products and adopting sustainable manufacturing practices. The future of PPR pipe manufacturing looks promising, with ongoing innovations aimed at improving the environmental footprint and expanding the range of applications. As the construction and infrastructure sectors continue to grow globally, the demand for high-quality PPR pipes is expected to increase, driving further advancements and opportunities in the industry.

In conclusion, PPR pipe manufacturers have significantly contributed to the modernization of plumbing and piping systems. Their dedication to innovation, quality, and sustainability ensures that PPR pipes will remain a preferred choice for diverse applications. As the industry continues to evolve, these manufacturers will play a pivotal role in shaping the future of efficient and reliable piping solutions.qnppr.com/top-ranking-10-best-ppr-pipes-brands-in-china-2024/